Table of Contents

What are Swivel Lift Point Fittings Used For ?

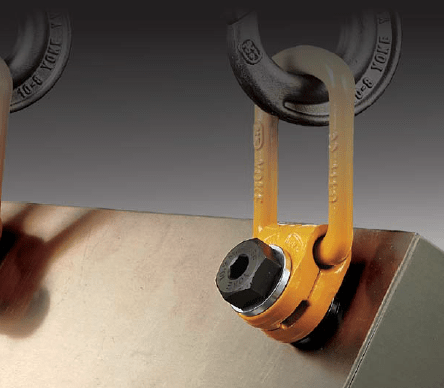

Grade 80 Yoke Swivel Lift Points

Designed to lift heavy loads, ranging from 0.75 to 15 tons, which need to be turned or flipped. With a maximum swivel range of 360°, GR8+10 rings can support the entire load in all mounting positions.

- Used in a wide varierty of industrial lifting applications

- Ideal for machinery and various lifting and lashing applications

What are the features of Yoke Swivel Lift Points ?

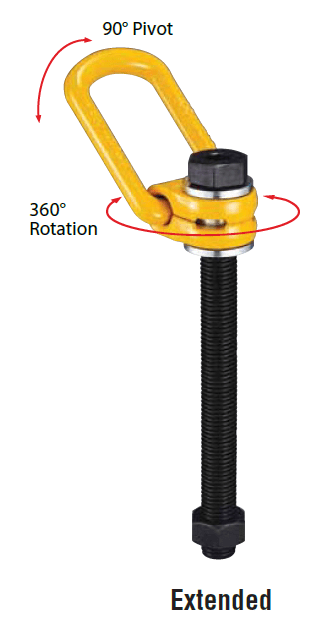

- 360° swivel with 180º pivot function.

- Hoist ring and bail are manufactured from quenched and tempered, forged alloy steel.

- Rated at 100% at 90º angle.

- Bolts are metric thread grade 10.9

- Standard and long bolt type available.

- 100% magnaflux crack detection, 20,000 cycle fatigue tested.

What are the advantages of using Swivel Lift Point Fittings ?

- Versatility: Swivel lift points can rotate in any direction, making them ideal for handling loads that need to be rotated or positioned in a specific way.

- Safety: Swivel lift points are designed to prevent twisting and binding of the sling, reducing the risk of accidents during lifting operations.

- Ease of use: Swivel lift points are typically easy to attach and detach from the load, making them ideal for quick and efficient lifting operations.

- Durability: Swivel lift points are often made from high-strength materials such as steel, ensuring long-lasting performance and reliability.

What are the differences over using an eyebolt ?

Overall, lift points offer a more versatile, safe, and durable option for lifting operations, compared to traditional eyebolts.

Eyebolts are not designed to have hooks attached directly to them. An approved shackle should always be fitted to the eyebolt and the slings are then attached to the shackle.

- Versatility: Lift points are designed to be used in a variety of applications, whereas eyebolts are typically limited to vertical lifting applications.

- Safety: Lift points are designed to prevent twisting and binding of the sling, reducing the risk of accidents during lifting operations. Eye bolts, on the other hand, can be prone to twisting and bending, which can be dangerous when lifting heavy loads.

- Ease of use: Lift points are often easier to attach and detach from the load than eyebolts, making them ideal for quick and efficient lifting operations.

- Durability: Lift points are often made from high-strength materials such as steel, ensuring long-lasting performance and reliability. Eye bolts, on the other hand, can be prone to corrosion and fatigue over time.

- Load capacity: Lift points are typically rated for higher loads than eyebolts, making them a better choice for heavy lifting applications.