RUD ABA Weld on Lift Point

RUD ABA Weld on Lift Point

The RUD ABA Weld on Lift Point has :-

- 4:1 safety against breaking

- Patented markings for easy determination for withdraw of service

- Tempered base body & therefore wear-resistant

- Weld-on lifting point

- Safer alternative to current pad eye lifting devices

RUD ABA Weld on Lift Point

- Forged, no rattling noise or shaking even at strong ABA vibrations or shock loads, simple connection of lifting means possible.

- Clear marking of the minimum WLL for all loading directions.

- Requirements of the DIN 18800 are fulfilled by the

weld arrangement (circular fillet weld), this means non

occurance of contact/crevice corrosion due to the endless

weld seam (therefore suitable for outdoor constructions).

Material of weld-on-block 1.6541 (23MnNiCrMo52)

(please observe user instruction). - Patented markings for easy determination for withdraw of service.

- Tested and certified by DGUV

- Testing specifications: GS-OA-15-04:2012-05 Certificate-Nr.: OA 1451020.

- Phosphated surface.

- Significant product characteristics of the ABA are subject to property right claims.

- Simple and fast welding installation.

- Confirmation of the low temperature ability to −40°C by the notch bar impact test is possible upon request (before order is placed).

- Appropriateness for hot dip galvanising after welding has to be analysed process related and liberised.

- The WLL statement corresponds to the minimum WLL in all loading directions. Higher WLL possible when location and installation is optimised (compare WLL chart / user.

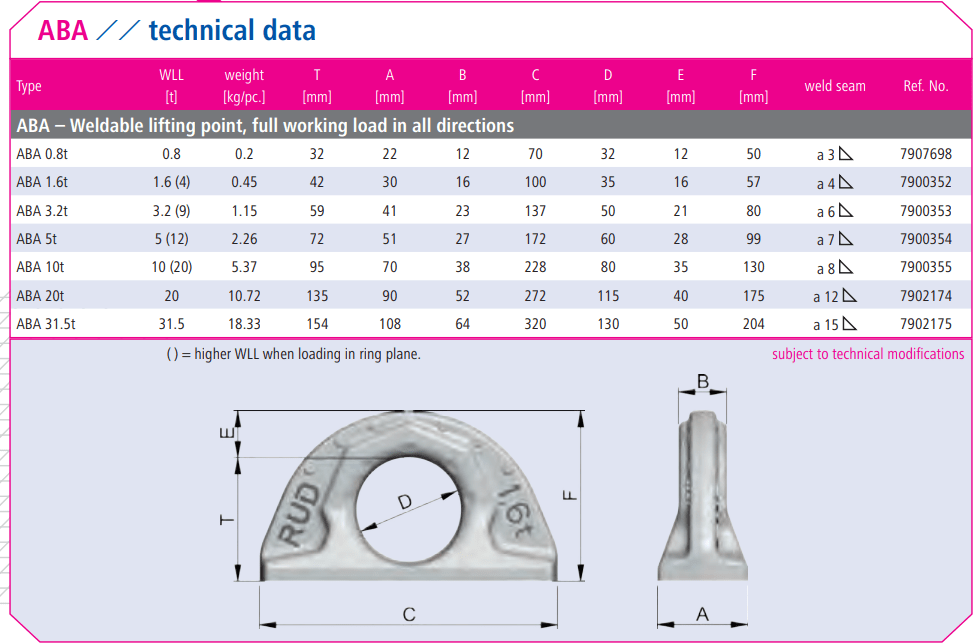

Part Numbers

0.8t - 7907698

1.6t - 7900352

3.2t - 7900353

5t - 7900354

10t - 7900355

20t - 7902174

31.5t - 7902175

View All Our Lift Point Fittings